What is PlanStudio?

PlanStudio is a finite capacity scheduling software designed considering the requirements of production planning and scheduling in the industry.

.png)

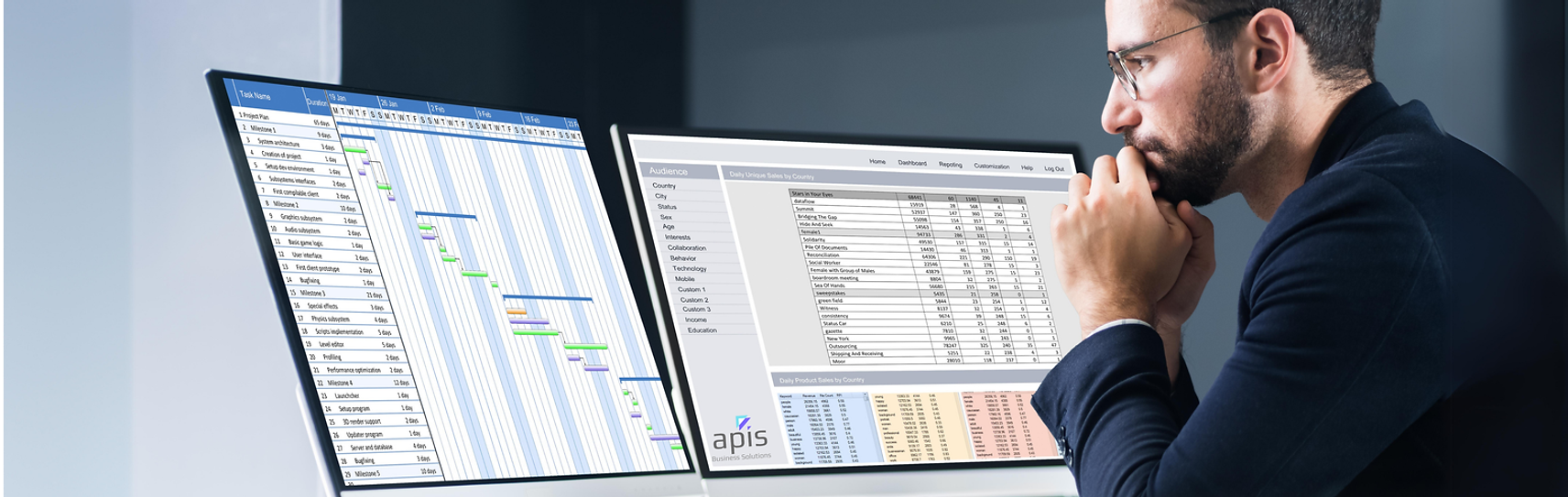

Every change made on the chart is made in a controlled manner together with all other constraints. In this way, an error-free chart can be created by considering many factors. All assignments and changes are made by drag-and-drop using a Gantt Chart where work times and resource occupancy are visualized. Thus, it provides both ease of use and a visual analysis environment.

What Can You Do With PlanStudio

Scheduling

Schedule using your machinery, personnel, and stock constraints.

Finished / Semi-Product Management

You can consider your stocks when planning for finished and semi-finished products. (You can make prioritization more accurate, you can minimize your product/semi-finished product waiting times by avoiding productions made earlier than necessary)

Operation Attribution

You can associate operations starting together or starting after the other is completed (“start to start” or “end to start”), and you can define specific delay predictions to these relationships. (As your associated operations will act within the rules you set, the possibility of making mistakes is eliminated)You can collectively manage your operations according to your relationship rules. (You can rearrange your plans in minutes)

Automatic Setup Management

You can automatically reflect the setups you define on the basis of references and the setup relationships between references to your plans. (With the automatic setup account, you can instantly see the effect of the changing sequences on the plan; you can quickly decide whether it is advantageous to manage by dividing the works)

Restrictive Manufacturing Elements Management

Include your restrictive parameters such as Mold / Tool / Fixture in the plan. Use your restrictive production elements other than machinery and labor as parameters in your plans..

Operation Planning

While planning your operations, you can assign different units/hours (uph) to your resources on a machine basis, and you can plan by taking these differences into account. (In this way, you can instantly evaluate the effects of using alternative sources and make the right decision) You can create different shift cycles (double shift, triple shift, etc.) for your machine groups, and use the number of people in these shifts as a factor in your plans. (You can manage your plans not only in terms of machine capacity, but also in terms of workforce capacity)

Break / Stop Planning

You can reflect your daily, weekly, monthly, yearly routine breaks and stops to your plans.

Non-Production Activity Planning

Plan your non-production activities such as Breakdown / Maintenance / Trial / Training. Apart from production, you can reflect the influential factors in your plans.

Real-Time Gantt Management

Change your job quantities in real time on Gantt. You can revise the values such as the amount of work / cycle time / personnel that you define by default, specific to that work piece.

Plan Quality Measurement

You can internally compare the scenarios you derive from the "key performance indicators" (kpi) (total job time, total setup times, machine efficiency, etc.) that you have determined. (By creating alternative plans, you can choose the most suitable one among the alternatives in the light of the data. You can analyze the effects of the changes made on the plan numerically.)

Monitoring Production Plans

Observe the plans for the individual production stages together. You can manage the plan you have created by seeing it with the previous and next plan levels. (By seeing the plans of more than one level together, you can see the delays with the previous and next stages. It prevents delays and time losses, and you can synchronize between the plans).

.png)

Why Do We Need Scheduling?

Although all ERP systems, including the most well-known and used ones in the industry, allow to manage the basic supply chain and production operations in enterprises, this management is carried out in a fiction that assumes endless capacity, where there are no constraints, due to their scope.

The main reasons why ERP outputs cannot be used directly are:

-Planned work orders are set up with production times independent of quantity.

-Efficiency differences between production sources are not taken into account.

-Factors such as differences in preparation times (setup), breaks and postures cannot be taken into account.

-Restrictive factors such as mold, apparatus, fixture are ignored.

- Considering the situations that develop outside of planning and require revision (order changes, malfunctions, lack of personnel, mold / apparatus failures, etc.), it is very difficult and time consuming to manage especially unexpected situations with standard methods.

Here's How Planning Works With A Standard ERP:

Relevant orders and forecasts are entered into the system.

Planned work orders for the orders are created in line with the internal production times and route information.

Production starts by converting planned work orders into production orders.

However, this process is quite insufficient to create a viable plan. For this reason, planning departments generally continue their detailed scheduling operations on "Excel" by using these outputs.

If it is to be explained with a sample company application;

In company A, the production planning process is carried out by three different planning engineers in three different locations. Each planner tries to manage the production data they receive from ERP from Thursday to Sunday with the visuals they create on "Excel".

Factors such as synchronization between production operations (operations start together or start after the other is completed, etc. production priority / succession relations), shift cycles, number of personnel in shifts, mold apparatus conflicts, products that cannot be produced at the same time, stock situations, setup times taking into account;

-Which product will be produced in which machine, with which unit/hour (uph),

-Which product, which operations, on which machines,

- Preparation (setup) transition times between products,

-The number and order of operations of the products are analyzed with "Excel".

All these data are not unique in the system and are open to manipulation and error, entirely at the initiative of the planners. If we put aside the workload and pressure on the planners, the inconveniences caused by the systems being built on people and the continuous crisis management measures eliminate the effectiveness and efficiency of the planning to a great extent.

In some cases, revision can become more difficult and complex than making the plan from scratch. Since the plans require constant revision due to changing situations, any change made for a single product creates chain effects within the system integrity. This situation creates the need to recheck all parameters for the whole process. However, the whole process becomes error-prone, as classical methods cannot provide error-preventing control for a planner in this process.

In addition to all these negativities, the personnel from whom process improvements are expected cannot produce qualified work due to the non-value-added loads of the system.

Why PlanStudio

The main development purpose of PlanStudio is to provide a fast, dynamic and reactive planning environment where data can be managed relationally and visually.

.png)

Relationality

Ensuring that every assignment made on the chart is controlled together with all constraints.

.png)

Visibility

All assignments and changes are made by drag and drop method with a gantt chart where job times and resource occupancy are visualized.

PlanStudio brings together all the necessary parameters for your planning within these two basic principles and offers you a working environment that allows you to make accurate, fast and measurable plans. It is easy to use and interactive.